Medical Device Manufacturing Capabilities

Sterling provides complete, end-to-end solutions, and we regularly manufacture all or most of our clients’ medical devices’ components. From single-use disposables to complex electronic devices… we have the technologies, skills, and experience to meet our customers’ diverse medical device manufacturing requirements; we’re proud to have produced a broad spectrum of market-disrupting products in our decades-long history as a top contract manufacturer for the medical device industry.

CNC Machining

- CNC Milling – 3, 4 & 5 axis milling

- CNC Turning – up to and including 7 axis turning with live tooling and sub-spindles

- CNC Threading

Injection Molding & Low Pressure Molding

- Multi-cavity insert molding

- Class 7 Clean Room Capability

- Complex Over-Molding (metals and plastics)

- Low pressure Over-Molding of electronics (encapsulation for biocompatibility)

- Wide array of Medical-Grade Resins

Class 7 (10,000) Clean Room

- Sterile pouch and tray sealing

- Assembly – kitting and packaging, IFUs, labeling

- Low to High Volumes

- Sterilization Management (Gamma and ETO)

- Pad printing, laser marking

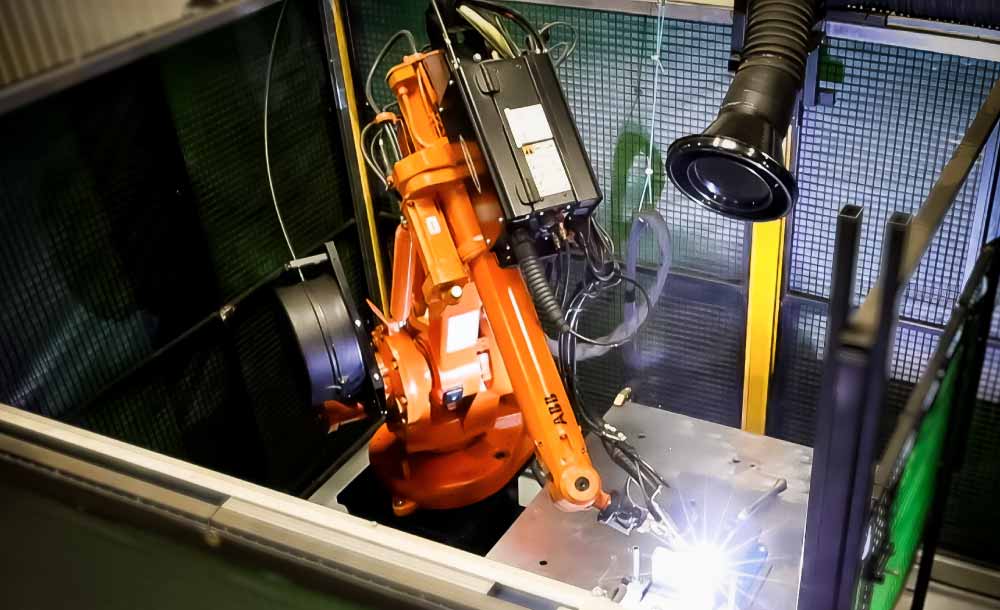

Welding

Robotic, Manual & Ultrasonic

- MIG and TIG (robotic and manual)

- Laser Welding (small format)

- Ultrasonic Welding

- Ultrasonic Heat Staking

Metal Finishing

- Polishing – Wet and Dry

- Bead blasting

- Anodization & Chrome Plating

- Powder Coating & Anti-Microbial Painting

- Electro-polishing

- Ultrasonic washing

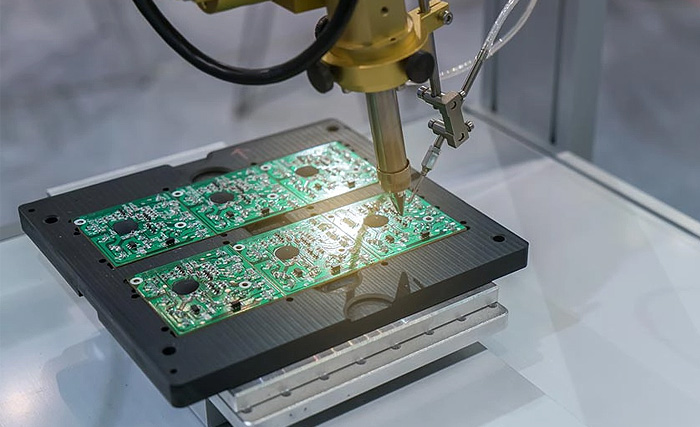

Electronics

- Soldering

- ESD assembly (Electro Static Discharge)

- PCB testing

- Post assembly testing

- Multiple partners for design & production of PCBs

- Optics

Laser Tube Forming & Processing

- Large format 3KW 3-D fiber tube laser

- Small format for metal needles and tubing

- High throughput, high repeatability

- CNC tube forming and bending

- Laser marking

Assembly & Packaging

White Room & Clean Room (Class 7)

- Sterile pouch and tray sealing

- High speed packaging lines

- Full packaging development including box types, labeling, artwork, etc.

- ESD Safe (Electro Static Discharge)

- Robotic Pick and Place

- Shrink tube application

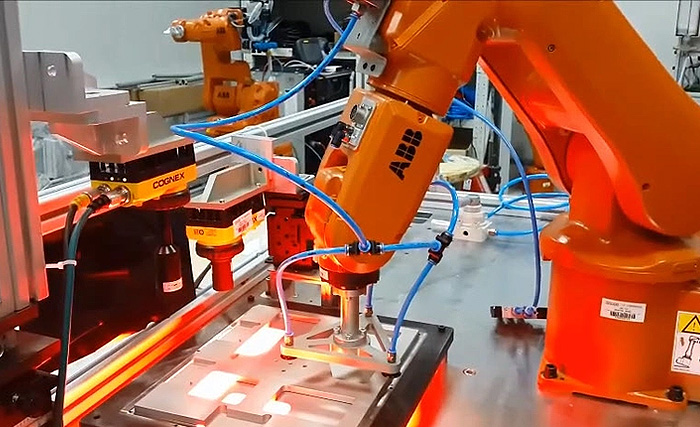

Automation

- High speed assembly

- High speed packaging

- Robotic Pick and Place

- Vision Inspection

- Inter-process Integration